Gaskets for Plate Heat Exchanger

We are the largest manufacturer of Gaskets for Plate Heat Exchangers. The High performance of our gasket material and an in-depth understanding is what sets us apart from the rest.

Wide- Gap PHEs

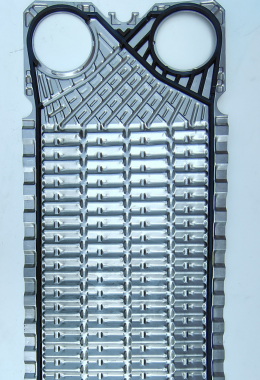

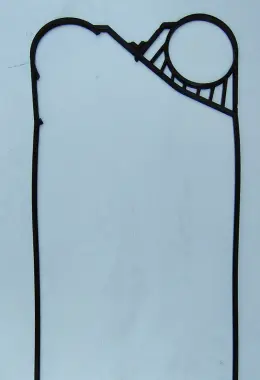

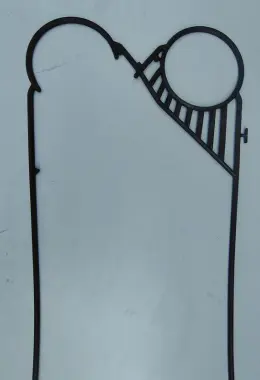

Plate and Gasket for T20S type PHE

A well-engineered gasket makes all the difference. Everyone deserves one — are you getting the quality you should?

Plate for T20S type PHE

The right port liner protects your PHE—and your peace of mind. Is yours built to last?

Gasket for T20S type PHE

A ready spare plate pack means zero downtime when it matters most. Are you equipped to stay ahead?

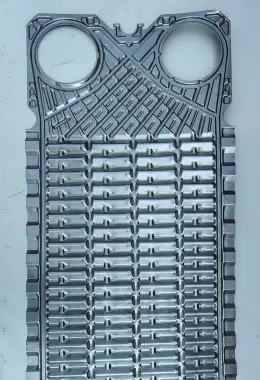

Spare Plate for FA184 type PHE

These Seals often known as Dome Seals are energised using compressed-air to provide pressure-tight sealing within a dome valve for fast cut-off and flow regulation

Spare Plate with Gasket for FA184 PHE

Resilient Rubber bonded to a rigid backup ring makes it a Cartridge type liner for a Butterfly type Valve.

FFKM O-Rings

Perfluoroelastomer (FFKM) is a high-performance synthetic rubber known for its exceptional chemical resistance and thermal stability. Learn more...

O-Rings

An O-Ring can the simplest and yet most critical part of a Sealing system. Comes in many forms dictated by the end-use. It may be used in Ultra low or Extremely High Temperatures. Comes in many avatars like HNBR, Viton-G, Silicone, Nitrile, EPDM to name a few